Surface production of negative-ions in hydrogen plasmas: comparative analysis of different surface materials

Résumé

Low pressure negative-ion sources find applications in several fields such as particle injection in linear accelerators or cyclotrons, surface analysis by SIMS, or neutral beam injection for magnetically confined fusion. These negative-ion sources rely on the process of negative-ion surface production, a process in which positive ions or atoms scattered from a plasma wall capture one or two electrons from the surface and lead to the production of a negative-ion. This process is occuring in any plasma source working with an electronegative gas but the negative-ion surface production yield is usually very low. In negative-ion ion sources a surface material having low-work function is employed to favour electron capture and negative-ion emission yield. The most common low work function metal used is Caesium (work function = WF = 2.1 eV versus 4-5 eV for common metals). Caesium vapour is injected in the plasma and deposit on the plasma chamber walls creating a low work function layer which favour negative-ion surface production. However, caesium drawbacks push to the use of other materials. In this contribution we are exploring several alternative materials for negative-ion surface production with the aim of detailing surface processes at play. We are particularly interested in dielectric materials for which it is known that electron capture by an incident particle is made more difficult by the high energy required, but electron loss to the surface from the negative-ion created is greatly reduced due to the presence of a band gap. To that aim a conductive ceramic, the electride material C12A7, having a low work function (WF = 2.4 eV) and a band gap, is compared with a low work function metal, Gadolinium (WF = 2.9 eV). Also, several diamond layers are compared together. In particular we have made the first study of negative-ion surface production on a phosphorous doped diamond layer (type n doping).

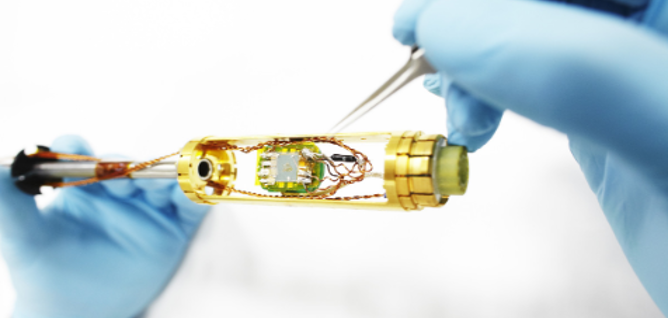

Measurements are performed in an ICP reactor at 2 Pa and 150W injected power. A negatively biased sample material is placed in the middle of the plasma chamber 40 mm away from a negative-ion detector, being whether a magnetized retarding field energy analyser or a mass spectrometer. Positive ions from the plasma bombard the sample and form negative-ions, which are then accelerated toward the detector and collected. The interaction of the plasma with the material lead to an evolution of the surface state. In order to collect in-situ information about changes of surface electronic properties due to plasma exposure a photoemission yield spectroscopy (PYS) diagnostic has been developed to measure material work-function.

In this contribution, negative-ion and WF measurements will be presented with a focus on in-situ photoemission yield spectroscopy. WF measurements will be compared with negative-ion yields and tentative correlations will be made with the aim of determining the parameters influencing at most on negative-ion surface production. A clear distinction is made between metal-like and dielectric like materials behavior with respect to negative-ion surface production mechanisms.

Domaines

Physique [physics]| Origine | Fichiers produits par l'(les) auteur(s) |

|---|